In what way are these helpful? In this post, we’ll look at how and why policy impacts your inventory and whether or not the model is of any practical value to a business owner.

Firstly, you would probably only know what your inventory model is if you had an Inventory Management System (IMS). An IMS calculates and displays the inventory model item by item and on a dashboard for the selected group.

If your IMS has this capability, you may have noticed the model differs from your actual stock on hand and, almost without exception, it will be lower, sometimes even considerably lower than the actual stock on hand. For this reason, it is often regarded as not being at all useful or credible.

Typically, the model value will get the attention of a financial manager who, convinced that the businesses is carrying far too much inventory, will see this model value as the target to be achieved. At that level, the financial returns on the inventory asset would most likely be significantly higher than on the current value of stock on hand and so it is a very appealing target.

When the sales manager sees the model value, he or she will normally state with great concern that if the inventory were to drop to that level, there would be nothing left to sell.

Unless understood, the model value is often regarded as meaningless and, as a result, ignored.

So, what is the model? What does it mean? And how useful is it in managing your inventory?

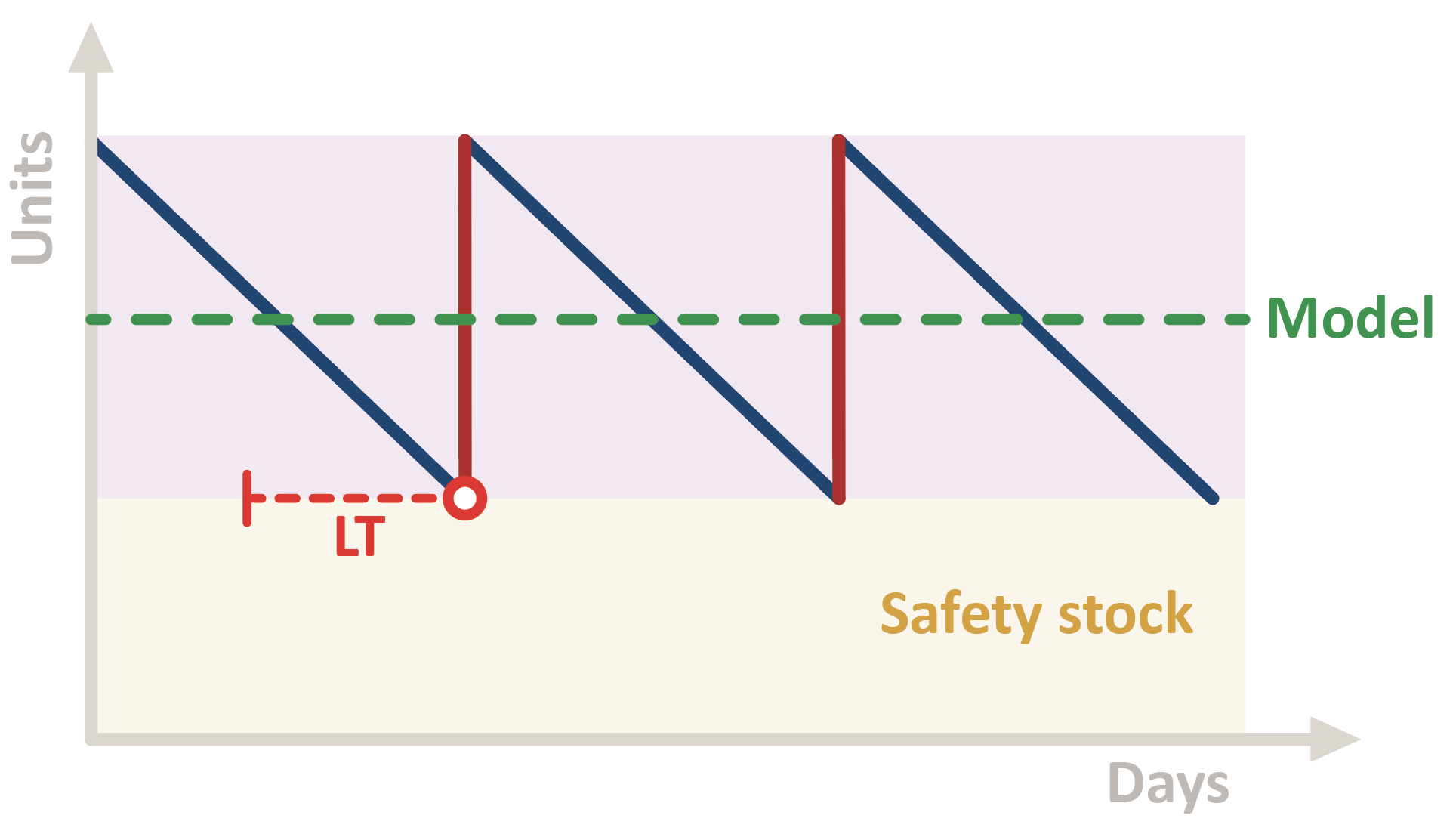

This diagram represents the theoretical projected stock on hand level over time of a stocked item in the perfect world.

The safety stock protects the item from stock out due to the risks of under-forecasting and / or late supplier deliveries and in the perfect world, of course, would never be required.

As the stock on hand drops to the safety stock level, a delivery, placed a lead time earlier, is received from the supplier and, being a perfect world scenario, the quantity received raises the stock on hand to it’s maximum level.

The average inventory level in this example is illustrated by the green dotted line.

This is the model or ideal inventory level. Take note that the actual stock on hand during the cycle, could be greater or less than the model.

Because the forecast may be seasonal and the order being placed provides for the immediate replenishment cycle(s), the Model Stock in the above example is the average inventory over the current replenishment cycle plus the safety stock required to cover the demand and supply risk factors for a defined target fill rate.

For a stocked item , the Model stock is defined as Safety Stock + 1/2 Replenishment Cycle.

The model is usually expressed in days of cover, in units and in value.

What purpose does the model serve for stocked items?

Because the safety stock is a factor in the model, for a constant target fill rate and replenishment cycle, an increasing “model days” indicates increasing supply chain risk. This could be the result of increasing lead times, higher forecast errors and poor supplier performance.

Note: The underlying assumption here is that the IMS dynamically adjusts the safety stock to accommodate these risk factors. For systems with static safety stock or “minimum levels”, this would not be the case.

A widening gap between the model and actual stock on hand could indicate increasing wastage or inefficiencies in the supply chain. Monitoring the trend of the gap is useful in determining whether the overall inventory performance is improving or deteriorating.

Classification plays a key role in determining the model. Items classified as non-stocked are “made to order” or purchased on a “back to back” basis only when there is firm demand. Because the objective is to hold zero stock, the model for these items is often set to zero. However, from a pragmatic perspective, a zero model does not always provide a realistic view for management and because there is typically some value of non-stocked items in the warehouse, other mechanisms are often used to determine a model value for non-stocked items.

Obsolete or redundant items are a clear-cut case. The model for these is zero.

Perhaps the key influence of the model is that the replenishment order quantity calculated by a correctly designed and configured Inventory Management System aims at aligning each item with it’s model. The inherent risks in demand and supply create inefficiencies that result in poor fill rates, excess and redundant stock that result in the gap between the model and actual stock on hand.

Now let’s explore how policy fits into this picture.

With “Policy” generally being defined as “a set of guidelines that determine the actions to achieve a specific objective”, then inventory policy provides the guidelines that determine the inventory model that determine the investment in inventory.

What influence does management have over inventory policy?

The one policy factor that is directly under the control of management is the target fill rate%.

To a degree, management has some control over the replenishment cycle and lead time. Your suppliers, to a great extent control these two factors.

Constantly striving to improve forecasting performance and working with suppliers by providing feedback on delivery performance and better planning information will lead to reduced supplier risk over the long term.

The benefit of these initiatives is a reduction in the safety stock and working capital tied up in inventory to achieve the same or even a higher customer fill rate%.

Often overlooked aspects are the importance of constantly improving employees inventory management skills and the systems they use. Your competitors are all dealing with basically the same supply and demand issues. Up-skilling your team and providing them with tools that provide better visibility and with the tools to more easily resolve the inevitable stock outs, potential stock outs, surplus orders and excess stock encountered on an ongoing basis, improves your business’s competitive position.